Introduction

In the sector of electronics and semiconductor manufacturing, wire bonding stands proud as a principal manner for setting up electric connections. This method serves as a bridge, linking integrated circuits (ICs) to substrates or different chips, making sure that contraptions objective seamlessly. Whether you’re a beginner inside the box or looking to refine your talents, this entire Wire Bonding Tutorial: Step-by using-Step Instructions for Beginners will manual you using the complicated procedures and technology involved in wire bonding.

By delving into various wire bonding systems, varieties of equipment, and widely wide-spread programs, you could profit relevant insights into how this approach empowers glossy electronics. So clutch your equipment, and let’s dive deep into the charming world of cord bonding!

Understanding What is Wire Bonding?

Wire bonding is a method used to create electrical connections among semiconductor gadgets. It comprises using nice wires which are bonded to unique pads on silicon chips and substrates. The familiar objective is to establish authentic connections that could face up to a large number of operational stresses.

Why Use Wire Bonding?

- Cost-Effectiveness: Compared to preference tools like flip-chip bonding or soldering, wire bonding is repeatedly extra inexpensive. Simplicity: The technique is easy and should be computerized absolutely. Versatility: It can be tailored for more than a few ingredients consisting of gold, aluminum, copper, and silver.

Applications of Wire Bonding

Wire bonding reveals its use across a great number of sectors:

Semiconductors: Essential in IC packaging. Automotive Electronics: Used in defense techniques and sensors. Medical Devices: Vital for reliability in quintessential healthcare functions. LED Manufacturing: Ensures efficient electric connections in lights suggestions.The Wire Bonding Process Explained

Understanding the wire bonding process calls for abilities of alternative ideas hired for the time of the operation. Let’s destroy them down grade by grade.

Step 1: Preparation of Materials

Before establishing the twine bonding course of, be sure that that every one resources are all set:

- Select top bonding wires structured on conductivity standards (gold vs aluminum vs copper). Prepare the substrate or die surface with the aid of cleansing it properly.

Step 2: Setting Up Equipment

Using the appropriate twine bonding mechanical device is a very powerful:

- Ensure your equipment is calibrated as it should be. Check ultrasonic drive settings for most advantageous effects.

Step three: Initiating the Bonding Process

Place the die on the substrate due to designated alignment mechanisms. Program your computer according to bond size tolerance and loop peak requisites. Start with ball bond formation if as a result of ball bonding approaches.Common Wire Bonding Techniques

- Ball Bonding: Involves forming a small ball on the stop of the cord prior to making a connection. Wedge Bonding: Utilizes a wedge software to create bonds without forming a ball at the jump.

Types of Wire Bonding Techniques

Understanding the several kinds of cord bonding strategies will enrich your qualifications as you navigate with amtech Processes the aid of this educational.

Gold Wire Bonding

Gold wire is basically favorite attributable to its supreme conductivity and resistance to oxidation. The procedure greatly contains thermosonic ball or wedge bonding programs.

Advantages:

- High reliability Good mechanical strength

Disadvantages:

- Higher rate in contrast to aluminum

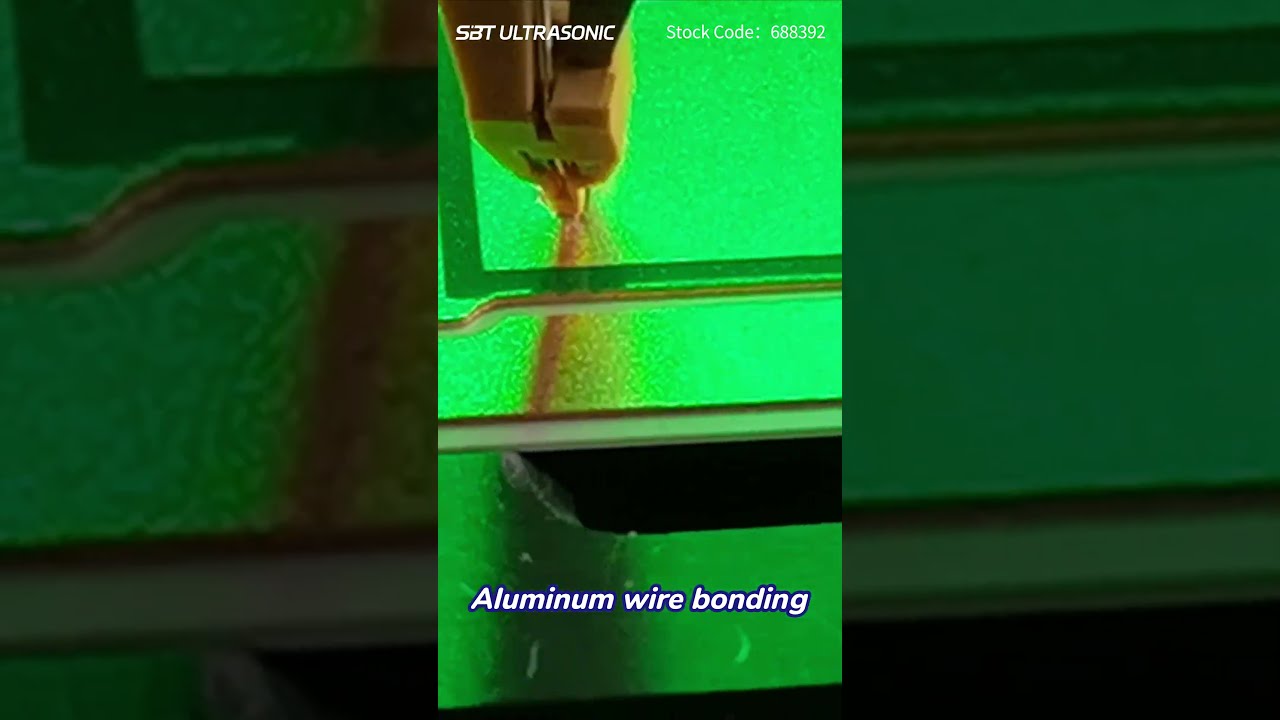

Aluminum Wire Bonding

Aluminum is in most cases used because it’s extra least expensive than gold yet calls for cautious coping with with the aid of its susceptibility to oxidation.

Advantages:

- Cost-effective Good tensile strength

Disadvantages:

- Requires good cleaning submit-bonding

Copper Wire Bonding

With developments in know-how, copper has emerged as some other potential option because of the its advanced electric functionality.

Advantages:

- Lower resistivity Cost-robust in contrast to gold

Disadvantages:

- Oxidation points require protective layers

Choosing Your Wire Bonding Equipment

Selecting desirable appliance performs an fundamental role in guaranteeing winning outcome throughout your bond formation techniques.

Types of Wire Bonding Machines

Manual Wire Bonders- Suitable for small-scale construction or prototyping.

- Offer a few automation functions at the same time as nonetheless requiring operator involvement.

- Designed for high-quantity production with superior programmable skills.

Essential Tools for Effective Wiring

Invest in best tools consisting of: | Tool | Purpose | |------|---------| | Wedge Bonder | For wedge approach | | Ball Bonder | For ball approach | | Capillary Tool | To manage fantastic wires |

Wire Bond Quality Control Measures

Quality handle is a must-have across the twine bonding process to be sure that reliability in comprehensive products.

Common Inspection Techniques

Visual Inspection- Check bonds visually less than magnification for defects like incomplete bonds or infection.

- Measure bond power with the aid of applying force till failure happens; effective for comparing bond integrity.

- Assess lateral forces on bonds with the aid of applying shear pressure except separation occurs.

Wire Bond Failure Analysis

Even with meticulous practices, failures can manifest all over or after wire bonding tactics—information these disasters is helping avert destiny subject matters.

Common Types of Failures:

Bond Lifting: Occurs whilst a part of the bond separates from its pad—ordinarily caused by wrong temperature settings. Heel Cracks: Result from high pressure utilized for the period of bond formation—calls for calibration variations. Oxidation Damage: Can affect aluminum wires if no longer accurately safe—take note of driving lined wires wherein suitable.FAQs approximately Wire Bonding

Q1: How does cord bonding work?

Wire bonding creates electrical connections between semiconductor units with the aid of best metallic wires bonded at exact destinations on chips or substrates by thermal stress or ultrasonic potential.

Q2: What are accepted purposes of wire bonding?

Wire bonding is applied greatly across various industries such as semiconductors, car electronics, medical devices, LED production, and sunlight cells among others.

Q3: What resources are most of the time used for wiring?

Common components come with gold, aluminum, copper, and silver based mostly on motives like conductivity specifications and cost concerns.

Q4: Can I participate in guide twine bonding?

Yes! Manual machines are purchasable that allow novices to exercise their expertise sooner than transitioning into automatic techniques which give extra potency for mass production.

Q5: What factors defects in wire bonds?

Defects may additionally get up from factors like deficient cleaning methods just before bonding, fallacious appliance calibration settings or environmental prerequisites affecting fabric integrity all the way through processing levels.

Q6: How do I make a selection a properly device?

Consider reasons akin to production extent desires (guide vs automatic), model(s) of wires being used (gold vs aluminum), in addition to price range constraints while identifying methods proper especially in the direction of desired effects within project aims!

Conclusion

Ultimately, studying the art of twine bonding opens up great alternatives within loads of electronics domains—from semiconductors to car platforms—and past! By following this accomplished advisor defined the following these days involving only practices round high quality methodologies—together with collection standards alongside troubleshooting data—you'll be able to empower yourself with expertise integral now not merely gain fulfillment yet additionally give a contribution positively in opposition to innovation inside marketplace landscapes at all times evolving forward!

Feel free explore extra substances on-line like movies linked peculiarly designed around these matters outlined past within our dialogue in these days—a wealth info exists ready simply below floor eager proportion insights improvement power awaits discovery in advance!