Introduction

The semiconductor market is continually evolving, driven by the call for for sooner, smaller, and more useful electronic instruments. As we delve into the future of ribbon bonding in IC packaging, it becomes crucial to consider how developments in wire bonding know-how are shaping this domain. In this text, we're going to explore different features of ribbon bonding, its packages, tactics, and the components influencing its future trajectory.

What is Wire Bonding?

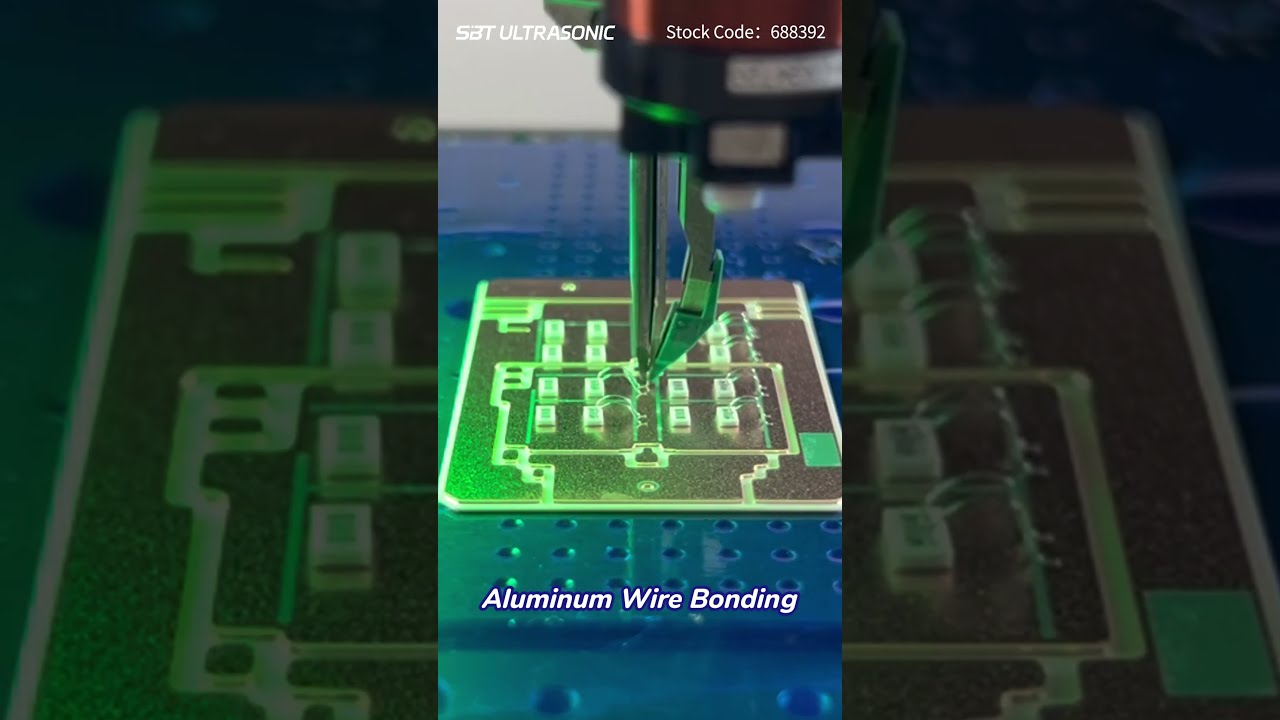

Wire bonding is a indispensable task in semiconductor production that establishes electrical connections between an built-in circuit (IC) and its equipment. Utilizing a range of cord bonding approaches—including gold wire bonding, aluminum wire bonding, copper twine bonding, and silver wire bonding—brands intention to create mighty and good connections.

How Does Wire Bonding Work?

Wire bonding consists of various steps:

Preparation: The IC and substrate surfaces are cleaned to be sure that good adhesion. Wiring: A skinny wire is attached to the bond pads on either the chip and substrate by using really expert apparatus. Bonding Process: Techniques reminiscent of thermosonic or ultrasonic potential are utilized to create a trustworthy bond. Inspection: Quality regulate measures be sure that the bonds meet business requisites.The effectiveness of this procedure considerably impacts wire bonding reliability and ordinary product efficiency.

The Wire Bonding Process: An Overview

Understanding the intricacies of the twine bonding job can support brands optimize their ways for better results.

Types of Wire Bonding

Ball Bonding: Involves creating a small ball on the conclusion of the twine ahead of attaching it. Wedge Bonding: Utilizes a wedge-shaped tool to make connections with no forming a ball. Ribbon Bonding: Employs flat ribbons other than spherical wires for greater surface touch.Ribbon Bonding Process Explained

The ribbon bonding job uses a flat ribbon rather then average around wires. This method promises several reward:

- Increased surface field for improved electrical conductivity Reduced inductance superior to increased frequency performance Enhanced mechanical stability

Applications of Ribbon Bonding in IC Packaging

Ribbon bonding reveals dissimilar packages within IC packaging:

- Power modules Automotive electronics Medical devices LED manufacturing

Understanding Ribbon Bonding Technology

As technologies advances, so do the tools employed in ribbon bonding, impacting each efficiency and payment-effectiveness.

Ribbon Bonding Machine Specifications

When determining a ribbon bonding equipment, be aware:

| Specification | Importance | |--------------------------|-------------------------------------------------| | Speed | Faster manufacturing prices slash prices | | Precision | Accuracy ensures fine quality bonds | | Automation Level | Fully computerized machines fortify performance |

Innovations in Ribbon Bonding Equipment

The evolution of apparatus has led to really good innovations in:

- Process control Automation capabilities User-pleasant interfaces

These thoughts have made ribbon bonding greater out there to producers in quest of risk-free suggestions.

Comparative Analysis: Ribbon vs Wedge Bonding

While each techniques serve related functions in IC packaging, they vary fairly:

Bond Type- Ribbon bonding focuses on superior floor domain. Wedge bonding often achieves tighter bond configurations.

- Ribbon bonders are typically greater advanced however offer improved overall performance for extraordinary programs. Wedge bonders regularly deliver more straightforward operation however won't in shape the velocity or pleasant of ribbon bonders underneath assured prerequisites.

- Initial funding in ribbon bonder machines is also increased; however it, operational rate reductions can offset those charges over the years through greater yield charges.

Challenges in Ribbon Bonding Process Control

Despite its benefits, challenges stay inherent throughout the ribbon bonding procedure that want addressing:

Environmental Controls:- Dust and moisture can lead to illness.

- Regular trying out (like pull exams) is obligatory for putting forward effective output.

- Different substances require targeted parameters for choicest outcomes.

Future Trends Impacting Ribbon Bonding Technology

As we appearance in advance, a few trends will shape the long term of ribbon bonding in IC packaging:

1. Miniaturization of Devices

With shrinking tool sizes comes an higher call for for finer pitch wiring options reminiscent of micro twine bonding and extremely-first-rate pitch purposes that make use of progressed ribbon expertise.

2. Rise of Advanced Packaging Solutions

New packaging codecs like 3-D ICs will necessitate imaginative processes inside ribbon bonding techniques to satisfy problematic connectivity specifications efficaciously.

3. Integration with Industry 4.0

Automation and archives analytics integration into manufacturing methods allow precise-time tracking and changes in the time of creation cycles—bettering efficiency although cutting back expenses greatly.

Exploring Wire Bonding Applications Across Industries

Wire bonding plays an vital position throughout diverse sectors beyond semiconductors:

1. Automotive Electronics

In automobile purposes in which reliability is paramount resulting from environmental demanding situations (warmness exposure), superior cord-bonded connections verify function even below serious stipulations.

2. Aerospace Technologies

Aerospace factors necessitate physically powerful designs capable of withstanding vibrations; thus, using authentic wire-bonded connections is quintessential for venture success.

Wire Bond Failure Analysis: Addressing Common Issues

Understanding plausible failure modes helps mitigate hazards linked to wire bonds:

Incomplete Bonds: Causes come with inadequate energy settings or incorrect ingredients used all over binding procedures.

Oxidation: Environmental components like humidity can advertise oxidation on bond surfaces most desirable to reduced connection integrity through the years.

Bond Pad Damage: Excessive pressure or misalignment all over placement may well compromise pad integrity necessitating repairs or remodel systems which similarly complicate construction timelines.

FAQ Section

What supplies are largely used in cord bonding?

Common elements come with gold, aluminum, copper, and silver wires based on utility requirements regarding conductivity and payment considerations.

How does one want among gold vs aluminum twine bonding?

Gold presents finest conductivity but at a upper charge when compared to aluminum which grants supreme efficiency at scale down prices making it gorgeous for plenty budget-touchy initiatives even though nevertheless ensuring reliability.

What developments are being made in automation related to twine bonding?

Modern techniques integrate AI-elegant tracking programs enabling manufacturers to make expert decisions about creation flows based on proper-time information prognosis enhancing performance at the same time chopping blunders margins tremendously when compared opposed to handbook systems alone.

Why is analyzing bonded wires very important?

Regular inspections assist recognize defects early sooner than they propagate into bigger issues impacting usual product satisfactory guaranteeing excessive reliability across executed supplies in this case protecting visitor pleasure phases persistently all around product lifecycles!

How do environmental controls influence the high-quality of bonded wires?

Controlling environmental factors consisting of humidity ranges supports stop oxidation that may degrade bond integrity over the years thereby bettering lengthy-term reliability metrics associated with comprehensive products preferable not directly toward bigger buyer retention premiums!

What distinguishes wedge from ball versus ribbon kind bonds?

While all serve related services—the pleasing properties associated with each one system cater against alternative engineering desires elegant upon one-of-a-kind design constraints & necessities outlined at some stage in initial stages past implementation stages accompanied thereafter!

Conclusion

As we navigate by using advancements shaping "The Future of Ribbon Bonding in IC Packaging," it be evident that ongoing innovation coupled with meticulous attention towards high-quality regulate will dictate luck amidst aggressive pressures dealing with at the present time’s industry! By leveraging new applied sciences along everyday methodologies—producers stand poised now not best capitalize on emerging opportunities yet also drive sustained development Discover more trajectories ahead paving pathways towards extraordinary breakthroughs yet unseen!

In summary, working out these dynamics surrounding ribbons’ role within broader contexts enables comprehensive perspectives imperative whilst strategizing long term endeavors tied promptly again toward improving operational excellence completed by using optimized implementation innovations aligning carefully together across industry landscapes ceaselessly evolving over the years!