Introduction

In the complex international of semiconductor production, wire bonding stands as a pivotal method. This methodology serves to determine electric connections between the chip and its kit, making certain reliability and performance in digital wire bonding services devices. Among a range of elements used for wire bonding, gold and copper are the most in demand contenders. Each material possesses distinguished attributes that give a contribution to their functionality in diverse purposes. In this text, we shall delve into The Advantages of Gold vs Copper in Wire Bonding, exploring their qualities, advantages, drawbacks, and suitability for a variety of different types of cord bonding innovations.

Understanding Wire Bonding Process

The twine bonding process involves connecting thin wires from a semiconductor die to its equipment or substrate using mechanical and thermal potential. This technique is central for creating strong electrical connections that face up to operational stresses. The wires can also be crafted from various material, with gold and copper being the maximum oftentimes used.

How Wire Bonding Works

Wire bonding in the main employs both ball bonding or wedge bonding strategies. In ball bonding, a ball is fashioned on the finish of the cord until now it can be connected to the bond pad at the semiconductor die. Conversely, wedge bonding comes to using a wedge-formed tool to create an ultrasonic bond between the twine and pad.

What Is Wire Bonding?

Wire bonding is a serious interconnection know-how used especially in semiconductors. It facilitates communication between chips and their applications at the same time putting forward low resistance connections foremost for software overall performance.

Types of Wire Bonding Techniques

Ball Bonding Wedge Bonding Ribbon BondingEach technique has its merits centered on layout specifications and materials residences.

The Role of Materials in Wire Bonding

When deciding on material for cord bonding, considerations like money, reliability, conductivity, and thermal residences come into play. Let's explore how gold and copper measure up in opposition t each one other.

Gold Wire Bonding: Characteristics and Benefits

Gold wire bonding has been a favourite inside the enterprise because of several key merits:

- Excellent Conductivity: Gold's prime electric conductivity guarantees minimal resistance. Corrosion Resistance: Gold does now not oxidize surely or corrode, which raises long-time period reliability. Thermal Stability: Gold maintains good features below various temperatures.

Applications of Gold Wire Bonding

Gold twine is predominantly utilized in excessive-reliability functions reminiscent of aerospace electronics and clinical instruments through its potent performance.

Copper Wire Bonding: Characteristics and Benefits

Copper has received acceptance not too long ago as a result of its advantageous homes:

- Cost-Effectiveness: Copper is vastly less expensive than gold; in this case, it presents financial advantages. High Electrical Conductivity: Although rather less than gold's, copper's conductivity continues to be great. Strength: Copper bonds tend to be automatically greater than those made with gold.

Applications of Copper Wire Bonding

Copper is broadly used in client electronics the place rate-effectivity is paramount with no compromising an excessive amount of on reliability.

Comparative Analysis: Gold vs Copper in Wire Bonding

Conductivity Comparison

Both gold and copper show high-quality conductivity; nevertheless it:

| Material | Electrical Conductivity (S/m) | Cost in keeping with kg ($) | |----------|-------------------------------|------------------| | Gold | forty five x 10^6 | 60 | | Copper | 59 x 10^6 | eight |

This desk illustrates why copper is likely to be extra fascinating from a fee perspective in spite of a bit of diminish conductivity.

Reliability Factors

Reliability is primary when settling on material for exact functions:

- Gold excels in environments liable to corrosion. Copper’s susceptibility to oxidation calls for protecting measures however deals excellent mechanical force when nicely processed.

Wire Bonding Equipment Considerations

To reap finest outcomes in both varieties of twine bonding strategies, really expert methods performs a a must have role:

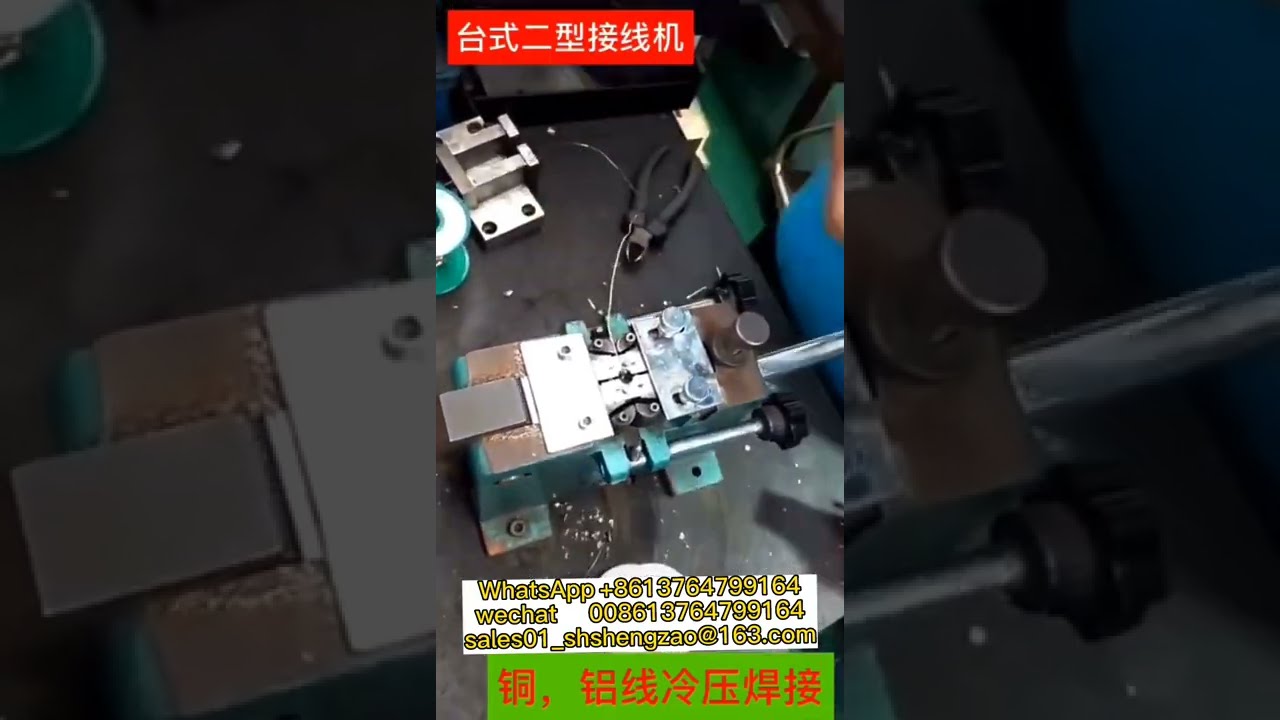

Wire Bonding Machine Types

Manual Semi-Automatic Fully AutomaticEach form gives various stages of keep watch over over the bond pleasant.

Wire Bond Inspection Techniques

Ensuring good quality manage in the time of wire bonding entails a considerable number of inspection methods reminiscent of:

- Visual Inspection X-ray Analysis Pull Testing

These checks support recognize talents topics early on.

Wire Bond Failure Analysis

Understanding original failure modes linked to either gold and copper wire bonds can assist mitigate risks:

Common Failure Modes

Oxidation Mechanical Stress Thermal CyclingAnalyzing these explanations allows engineers settle on good components based totally on software circumstances.

Wire Bond Quality Control Measures

Implementing strict caliber control measures for the duration of manufacturing ensures lengthy-time period reliability:

Techniques for Quality Assurance

Automated Inspection Systems In-line Testing Methods Detailed Documentation ProcessesThese measures are needed for keeping top requisites across all twine bonding packages.

FAQs About Gold vs Copper in Wire Bonding

1. What are the major transformations between gold and copper twine bonding?

Gold deals more suitable corrosion resistance although proposing outstanding conductivity but comes at a better fee aspect compared to copper that's extra within your means however can oxidize if no longer well treated.

2. Which subject matter is more stable for automotive purposes?

While equally will be used without difficulty in automobile electronics, gold's resistance to environmental explanations makes it foremost for excessive-reliability approaches within this region.

3. How does the payment impression resolution between gold and copper?

For prime-extent creation where money savings are integral, producers broadly speaking lean in the direction of copper; even though, applications requiring longevity can also justify with the aid of gold despite larger rates.

four. What inspection tools are steered all over cord bonding?

Common approaches incorporate visual inspections mixed with automated X-ray checking out to ensure every single bond meets first-rate specifications well beforehand relocating ahead with construction procedures.

5. Can I use either substances interchangeably?

Interchangeability isn’t recommended with out cautious consideration as each one material has different houses affecting bond strength below a large number of stipulations—seek advice desirable engineering policies earlier than making substitutions!

6. Are there any concepts improving those applied sciences?

Yes! Recent developments embrace better processing innovations tailor-made in particular for copper that escalate its efficiency traits even as minimizing oxidation disadvantages throughout the time of creation cycles!

Conclusion

In precis, realizing The Advantages of Gold vs Copper in Wire Bonding exhibits big insights into subject matter collection primarily based on software requisites—equally play obligatory roles inside electronics production landscapes at present! While gold’s unparalleled reliability shines by way of selected sectors like aerospace or scientific contraptions due broadly due its corrosion-resistant nature; conversely low-value opportunities consisting of copper dominate user electronics markets pushed with the aid of fiscal reasons! Ultimately deciding upon properly between them hinges upon balancing efficacy against price range constraints—a assignment made easier by way of grasped potential shared the following!

This finished exploration no longer handiest highlights key differences yet also hands execs with useful archives pivotal toward making informed picks across diverse commercial contexts—in some way shaping destiny traits within this ever-evolving area!