Introduction

In the realm of electronics, the connection among components is paramount. Among the myriad applied sciences possible, twine bonding stands proud as a cornerstone for organising nontoxic electric connections in semiconductor contraptions. This article dives deep into how wire bonding works, exploring loads of suggestions, appliance, programs, and possible pitfalls. With a focus on marketplace tendencies and improvements, this complete consultant objectives to provide insights and figuring out for engineers, technicians, and fans alike.

What is Wire Bonding?

Wire bonding is a vital system used in the semiconductor business to create electric connections between microchips and their substrates. By processes employing thin wires created from elements which includes gold or aluminum, manufacturers can gain tough interconnections necessary for system functionality. The twine bonding task has developed significantly through the years, adapting to satisfy the calls for of an increasing number of troublesome digital techniques.

The Wire Bonding Process: A Step-by way of-Step Breakdown

Preparation: The surface of both the chip and substrate ought to be wiped clean to eradicate contaminants which can affect bond satisfactory. Placement: The die is positioned on a bundle or substrate the use of genuine alignment methods. Bonding: A bonding instrument applies warm and power to create a bond among the wire and pad at the chip. Loop Formation: The wire is then looped to connect to an alternate pad on the substrate or die. Finalization: After all connections are made, the assembly undergoes inspection and checking out to ascertain reliability.Understanding Different Types of Wire Bonding Techniques

Ball Bonding

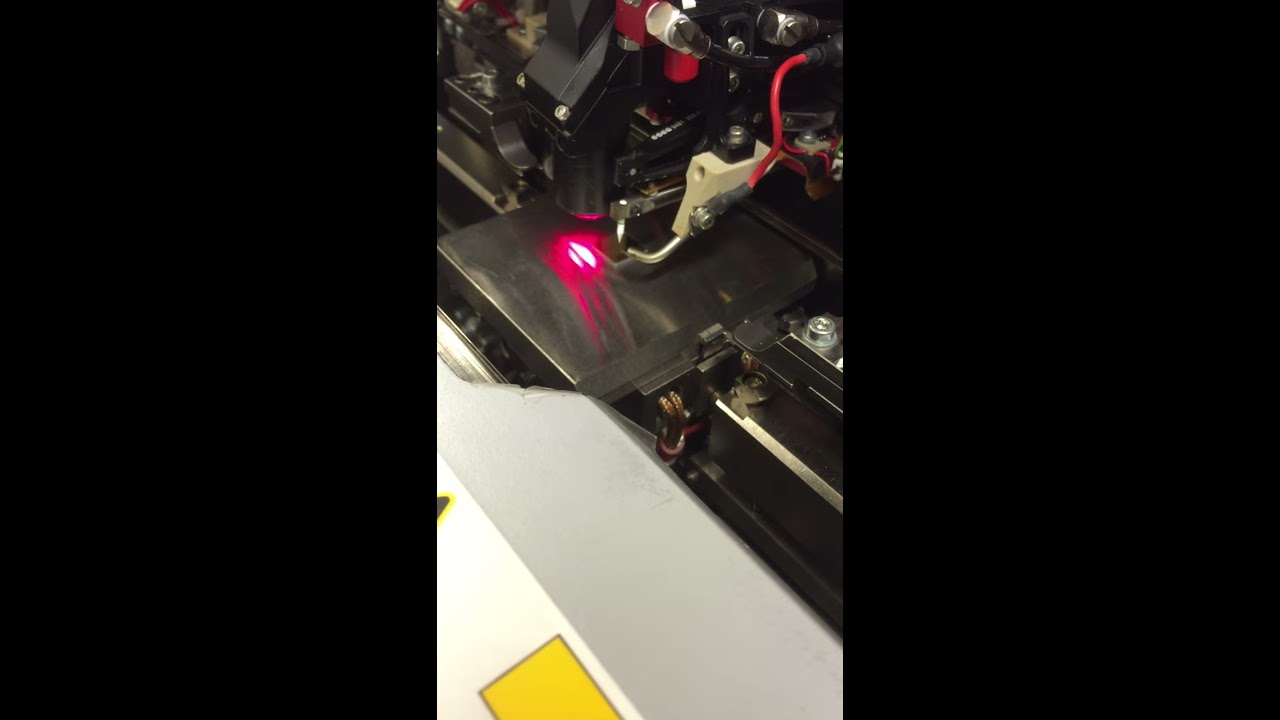

Ball bonding employs a ball-formed finish fashioned by melting a part of the twine with an electric powered arc earlier than that's bonded to the pad.

- Applications: Commonly used in prime-frequency applications on account of its means to deal with thermal enlargement improved.

Wedge Bonding

Wedge bonding makes use of a flat wedge instrument rather then a ball for making connections.

- Applications: Often applied in low-price packaging innovations the place house constraints exist.

Ribbon Bonding

This method comprises by means of flat ribbons as opposed to spherical wires for connections.

- Applications: Ideal for strength modules where increased modern-day ability is needed.

Material Choices in Wire Bonding: An Overview

The desire of cloth enormously influences bond power and reliability:

- Gold Wire Bonding: Offers extremely good conductivity but comes at a top class price. Aluminum Wire Bonding: More rate-efficient yet vulnerable to oxidation if no longer nicely managed. Copper Wire Bonding: Gaining popularity using its lessen rate and more advantageous conductivity when put next to aluminum.

Wire Bonding Equipment Essentials

When diving into wire bonding technologies, wisdom the gear is necessary. Below are some key accessories interested:

Wire Bonding Machine Types

Manual Wire Bonding Machines- Suitable for low-amount production and specialised tasks.

- Offer increased performance with a few automatic positive factors while nonetheless allowing operator involvement.

- Designed for top-extent production environments with evolved programmable gains.

Key Features of Modern Wire Bonders

- Precision manage over temperature and power enables for consistent bond exceptional. Advanced imaginative and prescient platforms permit truly-time monitoring of bond integrity. Programmability enables variation for a considerable number of packages with no full-size downtime.

Understanding Wire Bond Quality Control

Quality control in wire bonding approaches is obligatory for making sure lengthy-term reliability in semiconductor devices.

Inspection Techniques Used in Quality Control

Visual Inspection- Technicians contemplate bonds under magnification for defects like misalignment or incomplete bonds.

- Measures bond power by pulling on the bonded wire until it breaks; results imply the robustness of every connection.

- Assess bond integrity with the aid of making use of lateral power unless failure happens; useful for comparing adhesive houses.

Common Defects in Wire Bonding Processes

Understanding typical failure modes can assistance keep topics during manufacturing:

- Bond Lift: Occurs while tension exceeds force limits throughout operation. Heel Cracking: A crack close the base of the bond caused by mechanical rigidity. Incomplete Bonds: Result from inadequate warmness or stress right through formation strategies.

Evaluating Wire Bond Reliability

Reliability checks play a a must have function in figuring out how properly a product will practice through the years lower than several environmental stresses:

Factors Affecting Reliability in Wire Bonds

Environmental Conditions- Humidity and temperature fluctuations can lead to oxidation or corrosion over the years.

- Physical vibrations or shocks can weaken bonds if not designed as it should be.

- Over multiplied classes, even sturdy bonds may degrade through material fatigue or chemical reactions with surrounding resources.

Wire Bonding Applications Across Industries

Wire bonding technology unearths packages throughout a couple of sectors:

1. Semiconductor Manufacturing

Semiconductors depend closely on wire bonding procedures for powerful interconnectivity inside of included circuits (ICs).

2. Automotive Electronics

With expanding electronic content in vans, nontoxic wire bonding ensures safe practices-valuable purposes function reliably under harsh prerequisites.

3. Aerospace Systems

In aerospace programs wherein reliability should not be compromised, complex twine bonding innovations are employed significantly.

4. Medical Devices

Precision clinical gadgets utilize cord bonding era to make sure that suitable readings while holding longevity towards organic environments.

Wire Bonding Cost Considerations

Cost performs an major function when determining applicable material and techniques:

| Type | Cost Per Meter | Application Suitability | |--------------------|----------------|-----------------------------| | Gold | High | High-functionality purposes| | Aluminum | Moderate | General-rationale connections | | Copper | Low | Cost-touchy designs |

This desk illustrates how drapery resolution influences overall assignment expenses although additionally curious about performance necessities.

How Wire Bonding Works: An Insider’s Look into Industry Innovations

Continuous improvements are shaping long term developments within this quarter:

Innovations like extremely-high quality pitch ball bonds let denser packing configurations considered necessary for cutting-edge IC designs. New supplies inclusive of graphene-stylish wires be offering wonderful options given their uncommon homes mixed with decrease weight profiles when put next common alternatives like copper or aluminum. Industry 4.0 integrations enable good manufacturing talents wherein truly-time files tracking enhances strategy efficiencies in addition reducing prices related to rework due defects happening publish-manufacturing phases.FAQs about Wire Bonding Technology

FAQ 1: What substances are customarily utilized in wire bonding?

Common fabrics come with gold, aluminum, copper, and silver based on utility standards corresponding to expense constraints versus functionality demands.

FAQ 2: How does temperature impact wire bonding?

Temperature influences both adhesion properties at some point of formation methods consisting of fabric possible choices since a few forms can even changed into brittle at increased temperatures inflicting screw ups later down line.

FAQ three: Can I practice guide versus computerized wire bonding?

Yes! Manual machines let operators more flexibility while computerized ones beef up throughput costs in particular rewarding while managing widespread-scale productions.

FAQ 4: What checking out programs confirm fine manipulate after finishing up bonds?

Testing systems come with visual inspections alongside pull/shear tests deciding upon power integrity making certain sturdiness all around intended lifecycle utilization situations.

FAQ five: How do environmental components impact long-time period reliability?

Humidity phases along various temperature ranges make contributions against degradation phenomena in all probability greatest in the direction of premature screw ups until mitigated by protective measures taken throughout the time of fabrication stages themselves.

FAQ 6: Are there practising applications accessible focusing specifically on finding out approximately this science?

Absolutely! Many universities offer really expert guides even though online platforms host webinars aimed educating participants involved pursuing careers inside of this area providing beneficial experience in the direction of developments taking place right now!

Conclusion

In conclusion, realizing how twine bonding works serves as an quintessential facet of glossy electronics production tactics lately! From deciding on desirable components suited different purposes via making certain stringent fine controls applied across lifecycle levels – mastering these features permits helpful outcome throughout varied industries ranging from automobile sectors all means up into aerospace domain names the place operational dependability stays paramount! Through endured innovation coupled diligent analysis practices we will be able to appearance forward witnessing interesting transformative changes beforehand driven extensively emerging technologies redefining landscapes forevermore!

As we navigate as a result of these evolving paradigms at the same time let us embody new alternatives harnessed round superb utilization recommendations when fostering collaborative efforts eventually paving paths toward achieving stronger efficiencies maximized potentials realized with the aid of seamless integration methodologies mounted firmly rooted foundational principles underlying effectual administration frameworks validated guiding destiny endeavors undertaken mutually moving forward!